If you're wondering why a sale of 30,000 tons of Argentinian linseed is hanging fire in the winter of 1949, it is because linseed oil is a drying oil. That means that it dries out to form a hard, water impermeable film. If impregnated with molecules of base metals such as lead, a batch of drying oil will be even more susceptible to creating this durable, protective surface. Moreover, it will take on the colour of these molecules, which is often quite bright, as in the example of this street from Capetown, South Africa, which is the second Google Images search return for "brightly painted houses" this Saturday afternoon.

I am, of course, describing ready-mixed housepaint, a product that appeared on the market in the last third of the Nineteenth Century, making the magic of colour available an unprecedented scale, all but colouring the world, a point well made in Joshua MacFayden's 2017 McGill University Press imprint, Flax Americana: A History of the Fibre and Oil that Covered a Continent. It turns out that my favourite Calvin and Hobbes cartoon has more of a point to it than I ever suspected. It's also the prime constituent of linoleum, which I guess we saw coming.

Linseed oil's main competitor is tung oil, a treefruit oil largely produced in southern China in 1949, and therefore of uncertain supply in 1949. House paint (and lineoleum) are also construction materials, which Sir Stafford Cripps is trying to drive into scarcity as he attempts to curtail homebuilding in Britain while lacking the power to do so. There's also the issue of the price of imported base metals to consider.

And perhaps he was also faced with a bit of erosion of popular support if he makes it explicit that he needs the British people to continue to live in unsanitary hovels for a few more years when the means exist to put them in colourful houses with clean and durable linoleum floors. Good luck with that, Mr. Cripps!

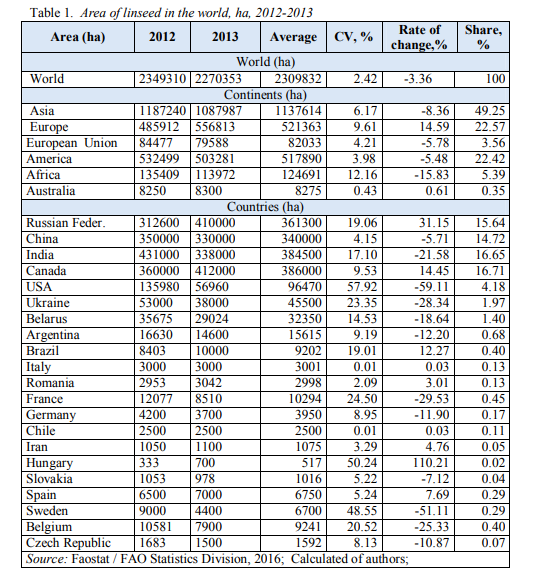

Unfortunately, my sources have not been able to tell me how Argentina came to have, and maintain, an effective monopoly on the global linseed market during the 1930s and 1940s. I have taken the liberty of clipping a table from an article that Vera Popvic has been kind enough to post to ResearchGate, leaving further reference to the article itself (autodownloading pdf) in the interest of, you know, the researchers' (Popovic, Mladein Tatic, Vladimir Sikora and Vladimir Filipovic) careers and all.

Canada, according to authoritative statistics, is the world leader in linseed production, and has been for a long time, although the amount it produces fluctuates significantly due to its use as a cover crop. The "northern cotton" has the shortest maturation period of the major cash crops and does well on new-broken soil. So if you are either sodbusting or just returning a parcel of land from fallow, and it does not look as though you will have the time between the beginning of ploughing conditions and first snowfall, flax, or linseed, is a good crop to sow.

Argentina is, I think, still more active on the world market. This is because, although the share of land devoted to the crop is relatively small, productivity per acre was, at least in 1949, about 30% higher than in Canada. Canada has overtaken it according to a slightly later table, but Argentina's productivity continues to be impressively high, and, I suspect, would look even better if investment per hectare were considered.

|

| Never mind the health benefits, "brown" flax makes theyolks yellower. |

The modern use of linseed has, however, changed significantly. Relatively little housepaint or "linoleum" is made with food oils these days. It is probably still used in soap, and the post-expression seedcake is still a popular fodder. Flax used to be a surprisingly unpopular food, considering. It contains a high proportion of omega-3 fatty acids, and these go rancid so quickly that you can sometimes pick up the "fishy" whiff off premium flaxseed breads in upscale Canadian grocery stores. (Just saying.) Nowadays, those same oils are deemed vital to heart (or is it brain, now? I forget) health, and if you don't want to buy --or shoplift, grrr-- them at the supermarket as vitamins, you can instead buy various flaxseed products or even byproducts like specialty eggs, and consume them that way. From what I've seen, I'd guess that chicken feed would be the destination of much of the Canadian linseed production.

The modern use of linseed has, however, changed significantly. Relatively little housepaint or "linoleum" is made with food oils these days. It is probably still used in soap, and the post-expression seedcake is still a popular fodder. Flax used to be a surprisingly unpopular food, considering. It contains a high proportion of omega-3 fatty acids, and these go rancid so quickly that you can sometimes pick up the "fishy" whiff off premium flaxseed breads in upscale Canadian grocery stores. (Just saying.) Nowadays, those same oils are deemed vital to heart (or is it brain, now? I forget) health, and if you don't want to buy --or shoplift, grrr-- them at the supermarket as vitamins, you can instead buy various flaxseed products or even byproducts like specialty eggs, and consume them that way. From what I've seen, I'd guess that chicken feed would be the destination of much of the Canadian linseed production.

This is not, by a long shot, all that can be said about linseed/flaxseed.

|

| The source for this is Amitkumar Jayendrasinh Jhala's 2010 University of Alberta Ph.D thesis, available here. |

Historically, the plant has been cultivated for its fibre. In common with hemp, jute and sisal, those bounteous heads of seeds are intended to be carried aloft over ground water and competing species on a long, strong stalk of cellulose bound together with gummy pectin and calcium ions, says Wikipedia, although there's clearly a significant amount of nitrogen in the binding tissue, just from the stink made in its fermentation/decomposition. Stripped out of this binding material, the stalks of cellulose create a bast fibre, characterised by good strength and drying properties, but poor elasticity (it wrinkles). It is also hard to dye.

Traditionally, linen was produced in large quantitites but in a decentralised way, for rope and twine, and in relatively smaller quantities for "homespun" clothing. One of the virtues of MacFayden's monograph is that he makes impressive use of Canadian census data to show just how complicated the "flax web" is. Where one might suspect that "homespun" means a small amount of flax grown on the farm for domestic use and piecework, it turns out that the traditional flax-growing economy of old Europe has been organised by "flaxers" for a very long time. Flaxseed is sold or otherwise provided to farmers, then grown either by the farmers or contractors employed by the flaxer on land rented from the farmer. This spares the farmer from having to invest in flax seed stock from year to year.

However, the commercial side of growing flax is only the beginning of the story. Preparation is long and complex. The strands must be first separated from the binding tissue, traditionally by controlled rotting underwater, which is probably the natural process for which evolution has shaped the plant's chemistry, explaining why the microorganisms found with flax are so congenial to the process. However, the results are somewhat contingent on the chemistry of the water itself, and it requires some skill to judge just how long the retting continues. Also, the waste water from the retting is toxic until treated (my sources do not say how), although quite nutrient rich.

Once retting is completed, the "flaxman" may pay rent in the raw material, or not. The stalks still need a two stage process, colourfully dubbed "scutching and retting," before they are ready to be spun. These processes can be mechanised, and the flaxman might be associated with a "flax mill," which, conveniently enough in North America, uses much the same equipment and industrial space as an old time sawmill. The intimate touch of the old "flaxman" thus arrived in upstate New York during the Napoleonic Wars, when the land was rapidly cleared and ploughed to provide the warring powers with lumber, grain and, as it turns out, industrial fibres. MacFayden's census-based investigation arrives in Canada in the decade before the Civil War, just in time for a rising industry to catch a tail wind from the Southern blockade, as Northern mills converted temporarily to a cotton/linen blend.

This early model could not be transmitted to the Great Plains. Instead, pioneering agribusiness firms like Archer Daniels cooperated with the US and Canadian authorities to replace the old "flaxman" with a corporate-and-scientistic approach. MacFayden places heavy emphasis on a USDA scientist , Henry Luke Bolley, also apparently a "pioneering football coach," who ran a (not-social) Darwinist operation at the Eureka (you cannot make this stuff up) Agricultural Station, near the North Dakota State campus at Fargo. The point of the operation was to sadistically torture flaxseed by growing it continuously on a plot that was rife with all manner of flax diseases. The resulting super-flax seeds would then be provided to farmers via Archer Daniels, ensuring a bountiful crop notwithstanding the various weakness to which flax was prone. not only flaxseed but "scientifically improved" flaxseed.

This early model could not be transmitted to the Great Plains. Instead, pioneering agribusiness firms like Archer Daniels cooperated with the US and Canadian authorities to replace the old "flaxman" with a corporate-and-scientistic approach. MacFayden places heavy emphasis on a USDA scientist , Henry Luke Bolley, also apparently a "pioneering football coach," who ran a (not-social) Darwinist operation at the Eureka (you cannot make this stuff up) Agricultural Station, near the North Dakota State campus at Fargo. The point of the operation was to sadistically torture flaxseed by growing it continuously on a plot that was rife with all manner of flax diseases. The resulting super-flax seeds would then be provided to farmers via Archer Daniels, ensuring a bountiful crop notwithstanding the various weakness to which flax was prone. not only flaxseed but "scientifically improved" flaxseed.

The blood-and-soilness of this was probably of somewhat less importance to actual farmers than is sometimes assumed. If they were going to use flax as an occasional cover crop rather than a continuous planting, they needed to buy seed somewhere. The idea that flax was fragile, or particularly disease prone, or "exhausted the soil" made for a convenient explanation for the wild fluctuation in plantations from year to year --but the economics of flax makes for a better one. Even Bolley had no answer for the permanent flax industries of Europe, and was flummoxed by Argentina's success given that that country's farmers lacked capital investment, hovering botanists, and even security of land tenure. ("But what about property rights being the foundation of prosperity?" The question seems to scream out of the notes of his early-50s visit to Argentina, according to MacFayden.

You'll notice that we've slipped through an easy transition from flax linen to linseed here. Flax linen obdurately refused to take off in North America, and MacFayden has a fascinating chapter on an intermediary stage characterised by "flax promoters" who relentlessly pressed on two weaknesses in the production web. First, while flaxseed could be harvested and threshed mechanically in the same way and with the same equipment as wheat, one of the factors that made it attractive to Great Plains farmers, flax linen had to be pulled from the ground by hand. Second, retting was an enormous pain in the ass, even when the flax was simply laid on the ground and dew-retted, which produced inferior fibre. To persuade farmers to embrace the risky and contingent crop (a critical part of the industry from time immemorial, as we've seen), the promoters constantly promised mechanical pullers and a modern, chemical process of retting. MacFayden characterises the main chemical retting process, that of the self-dubbed Chevalier Claussen (still can't make this stuff up) as alchemy, but my old Britannica makes it sound like a typical modern chemical retting process, albeit one using the old-time, organically-derived acids and caustics of the first generation chemical industry, and therefore thoroughly yucky as well as producing a second-rate product. Much more importantly, although the process was advertised as producing a "cottonised" fibre, the transformation of good bast fibre into bad ersatz-boll fibre at great expense is not the foundation of a successful business.

At one point in the interwar period, MacFayden tells us, Agriculture Canada had a special "fibre division" looking into fax promotion frauds, most of them claiming engineering or scientific breakthroughs in harvesting. And one can see why, when a US Post Office investigation found that was able to make almost $33 million disappear by channeling the funds of duped investors from his "Oxford Linen Mills" venture through Sterling Debentures. Mudge might have been caught in the end, but thirty-three million was a lot of money in 1913, so you can see why there was a long tail of flax linen-related patent trolling bullshit to come.

Meanwhile, out in the Great West, flax arrived more-or-less on its own in the old Hudson's Bay Colony days, promoted by Governor Simpson as a way to develop the rural economy of his crofter-colony-in-the-heart-of-America through putting out and craft industry. That being said, the native flax, Linum lewisii was already in use as a fibre plant and has the same desirable characteristics as fodder and reclamation crop already well known in the European species. It presumably established its value as a cover crop immediately, and was just sitting there when botanist-turned-US-Senator Edwin Ladd arrived to pick it up. Pure food (and pure soap) being a thing, he took on the paint companies on the "purity" of their oil, in the name of Archer Daniels, and made a living of it. He did not live to see the failure of the effort to save "flax," and, perhaps as a politician, might have seen the folly of trying to get farmers to grow flax by finding scientific excuses for raising the price of the seeds that companies sold them.

Or maybe not. It's hard to underestimate the cupidity of the crop of 1920. Whatever: The sod-breaking era was coming to an end in 1920, and so was the first wave of growth in the flax industry. Increasingly, eastern paint manufacturers were turning to Argentinian linseed, which could be brought in more cheaply by ship than western product could be by rail. (Evidently, it was also better product.) Archer Daniels and the Great Plains interest therefore turned its attention to protective tariffs, which seem to have had no effect whatsoever apart from perhaps crashing the Argentinian and world economies.

Which brings me back to the original paradox: Why was Argentina so much better at growing flaxseed? There's no history here of flax linen, although after reading MacFayden I suspect that there must have been a "homespun" industry to produce binder twine and such. It was all seed from the beginning. The agronomic logic was the same as in the north, and the supporting infrastructure underdeveloped compared with North America, as Bolley noted, despairingly. One is left to suspect that without scientists and patent trolls to distract them, Argentinians just tried harder.

In conclusion, flax is the crop of the future, and always will be.

No comments:

Post a Comment