|

| David Hounshell is the David M. Roderick Professor at Carnegie-Mellon and the author of From the American System to Mass Production, 1800-1932: The Development of Manufacturing Technology in the United States [1985]. You should read one copy and buy two. |

I started this series with a discussion that rambled on about farming, tractors, and ended with a discussion of the strategic consequences

of human resources shortfalls on the Eastern Front. To

some extent, that was a petulance.

All honour to the mighty Red Army of Workers and Peasants!

Anyone can get irritated by fanboy

enthusiasm. Talking about the deep operational art of Soviet forces, equipped

with the world’s best tank, winning WWII while the Allies footled about out west sure beats getting excited about the way that the superior

fighting qualities of the Waffen SS reflect its racial purity! It does have consequences, however. The first, a dead issue now, is the idea

of an unstoppable Red Army rolling over NATO to reach the Channel in three

days. In the dead politics of the 1980s, such talk had consequences, even if those seem pretty harmless in retrospect.

|

| Maybe it helped get Thatcher elected? Although even that doesn't do much for the thesis considering that the Russians lost. |

What's not important is the permanent misunderstanding that

basically asserts that “Asiatic” or “Eastern” countries are exempt from the

basic arithmetic of demographics because reasons. (Cloning tanks?) If Russia only had so many

working age men and women, how did they keep the Army up to strength while

manufacturing tanks and growing food? The answer is, first, that it didn’t,

and, second, Allied aid. Throwing up either answer, seems to require being realistic about demographics and economics, and since that might lead us to uncomfortable places, well, why not talk about the Russian steamroller, instead?

Take America: Just today, Amazon was trhing to sell me

another book about Pearl Harbour, with a subtitle something like “Awakening the

Sleeping Giant.” [?] This is, of course, a perfectly clear account of exactly what

happened. That 's why Admiral Yamamoto might have said it! The issue is, what made America a “sleeping giant?” Because if the

answer is demographic –that America in 1941 had a population of 137 millions

compared with Japan’s 73 (not counting Korea, Taiwan and Manchuria), then why

is the comparison not: “Japan picks on a country that is a little less than twice as powerful as

it, but, then, one that also had to fight Germany (and Italy, if it counts, and

then all those Balkan countries and Finland, so there’s that, and, besides,

Thailand was allied to Japan, so, wait, why the heck not, maybe China counted

for more than you’d think?”)

The answer, as far as Japan goes (besides China --"March of the Volunteers" link) is that

being a “giant” counts for more than population. America had a higher

GDP/person, reflecting higher individual productivity. I’m told that economists of the day then explained this in terms of a

higher ratio of capital investment to labour, but, if so, the advanced thinking

of economists hadn’t percolated to all sectors of informed opinion, because

your average Fortune editorial writer

was aware that American productivity/person had been rising steadily since at

least 1870, and did not always correlate with changes in capital investment

rates. They would talk about the higher natural endowment of land and resources

enjoyed by American workers, and also invention and technology, puzzles then as now.

This is not the place to answer profound questions about

technological change, innovation and productivity increases. I mean, everybody is answering those questions these days! Maybe, though, it's a good place to ask those questions. Eventually, such an exercise might even be useful for those who prefer answering to questioning.*

As the title says, the subject here is agriculture. It's pretty important, because the United States was the only major belligerent whose agricultural output

increased during the war, and that allowed it to feed much of the world through a six year conflict. There's not actually much mystery in the broad strokes of this, as “major” is doing a great deal of work here. Canada is only one of the minor belligerents to have experienced a similar trend, and I cannot believe that the war-winning rubber and palm oil production of Sri Lanka, or the wheat of Palestine and timber of Turkey, do not reflect similar trends. It's the details that concern us.

|

| The most important part of "awakening the sleeping giant is the precipitous fall in unemployment --or, to put it another way, the rise in labour force participation. Thanks, Yamamoto! |

The fate of agriculture in belligerent countries reflects

investment and labour allocation decisions, and the American trajectory tells us, in advance, what we

are going to learn about the

American farm sector.

|

| More workers equals more food. Rocket science! The source for these great graphics is an out-of-pring NBER monograph, Clarence D. Long, The Labor Force in War and Transition: Four Countries [1952]. The fourth country is Canada, and its curves look just like America, only less exuberant. |

To a point. Farm employment did fall in

America, and so did non-farm rural employment, in ways that probably reacted on farm productivity. In coal, the big issue of the winter of 1946--7, wartime production was maintained in spite of labour force reduction by exploitative methods that helped lead to postwar shortages. That is not, however, what happened in American agriculture. Rather, the roughly 20% decline in labour led to a rise in production, and, as Dr. Collingham likes to point out, the euthanasia of the American peasantry, a class dominated by, but by no means

confined to, Southern sharecroppers.

|

| We've seen this before, although not filtered. I've adjusted the Dutch tilt from the last version, at the expense of cropping E. S. Purrington's credit. |

That's Fred Anderson, of Ford County, six miles out of

Dodge City, bringing in his 37th harvest, with the help of his 19-year-old

son, Frank Jr., out on a twenty day harvest leave from the Navy.

They have 600 acres, a “clattering” 1934 Dodge light truck to move the

Andersons and their two harvest hands around the back forty, two combines, one 16 and one 17 years old,

a private elevator, and thirteen hours of dew-free light in which to work, with

time out for lunch, and will have 8000 bushels by the end of the harvest,

yielding $13,600 at $1.70/bushel. Frank makes good money, all the more since he only needs to cover off two harvest hands to farm 600 acres! Kansas farms like the Anderson's will produce 215,000 bushels of wheat, one-fifth of the

nation’s wheat crop this year. If those farms are just like the Anderson's, only 300 (of less than 300 square miles land!) will produce those 215,000 bushels. It's really kind of astonishing, put that way.

Talking about productivity increases in American

agriculture brings us round to capital investment, for which, on first pass,

the tractor serves as synecdoche. Mr. Anderson's tractor is the most prominent subject of Purrington's photograph, above. Without it, there is no way that six hundred acres is a family farm. In Russia, there is a very direct correlation

between a shortage of tractors and a decline in farm productivity, while in

Britain, tractors were very directly taken as a farm production input –much to

the benefit of manufacturers trying to get priority allocations for tractor production

lines.

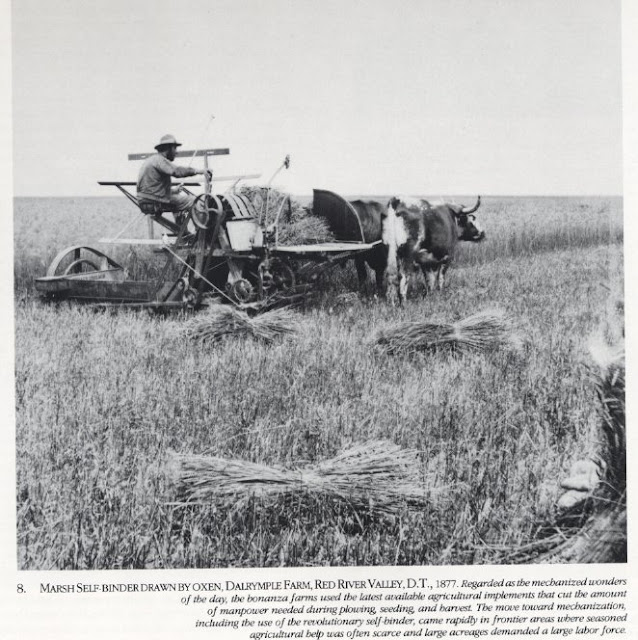

Having conjured “production lines” from the vasty deep, I am ready to come around to the “American

system of mass production.” Dr. Hounshell’s history of the same (seriously;

read it already!) begins, after all, with Chicago’s McCormick reaper factory.

Every spring of the 1880s, the factory would roll out a new year’s crop of

reapers, which would go off to the “bonanza wheat lands” of the Red River of

the North, along with the factory’s workers, who would operate the reapers on a

summer furlough, producing cash crops of wheat to feed Europe’s teeming

millions. And every winter, the reapers would rust under the naked sky, because

the economics of bonanza wheat made it cheaper to buy a new reaper than to

build a barn to store it in. (A logic that had not entirely disappeared from

the Great Plains by 1945, as Fortune’s agricultural

correspondent, Ladd Haystead, reminded us in the special housing issue.)

|

| This isn't a very good example, since the Wikipedia rticle is discussing the independent contractors, who very definitely did take care of their machines. |

McCormick’s reaper factory had disappeared from the public

consciousness by 1946, replaced by the right-wing McCormick press of Dick Tracy and Little Orphan Annie. By that time, mass production meant a "Mr. Ford." Last time, I talked a little bit about the Fordson Tractor, a notoriously

unsucessful Ford manufacturing diversion, for which Henry Ford probably gets

more flack than he deserves.

So why did Mr. Ford fail to mechanise Northg American

farming in the 1920s, when, as the mass draft horse and horsemeat exports of

1946 so clearly show, the war succeeded? Interesting question! And by

“interesting,” I mean, I want to

introduced another digression –this time, the A. O. Smith automatic frame

factory, which popped up as a retrospective in a November, 1946 Fortune article on the latest hype about "automatic factories."

I hope I’m not alone in finding it fascinating that two (Canadian!) hypsters are talking about a

computerised, automated factory in 1946, hardly hampered by the lack of

a “computer” paradigm to dress up their nonsense. (From the look of things, Leaver and Brown are about to chose the wrong side in the imminent "computerisation" versus "cybernetics" divide and followed Norbert Wiener down in flames.) What matters is that Fortune

heads the story with a callback to its 1934 article about the Smith

factory. The technology is new, but the hype is old! The Smith factory, however, was no con job. It really could produce a new auto frame in 8 seconds, the problem being that this was more than the industry needed.

Well, part of the problem, anyway, since the frame-built automobile was already on its way out. Citroen would launch the first unibody car, the Traction Avant, in 1934, and the Volkswagen Beetle's hybrid body would deal the small vehicle frame its death blow in the early 50s. (Just to soften the blow of observing the way that automobile innovation appears to be happening in places other than Detroit, I should probably mention the Chrysler Airflow.)

A. O. Smith, a 140-year-old company, now held by the fifth generation of the Smiths, is a numble and innovative international manufacturing company that knows when to get into and whent to geto out of subsidiary lines. (Mostly, "when to get out of" is "since the 1990s." Why be a conglomerate when you can focus on achieving a monopoly in boiler and water heater sales?) Had America been reduced to buying a single model of car, made with a single frame, the A. O, Smith plant could have gone full blast forever, and many, many labour hours could have been saved. At least until the mid-Fifties, when this hypothetical all-Model-T industry was swamped with superior European imports.

Well, part of the problem, anyway, since the frame-built automobile was already on its way out. Citroen would launch the first unibody car, the Traction Avant, in 1934, and the Volkswagen Beetle's hybrid body would deal the small vehicle frame its death blow in the early 50s. (Just to soften the blow of observing the way that automobile innovation appears to be happening in places other than Detroit, I should probably mention the Chrysler Airflow.)

A. O. Smith, a 140-year-old company, now held by the fifth generation of the Smiths, is a numble and innovative international manufacturing company that knows when to get into and whent to geto out of subsidiary lines. (Mostly, "when to get out of" is "since the 1990s." Why be a conglomerate when you can focus on achieving a monopoly in boiler and water heater sales?) Had America been reduced to buying a single model of car, made with a single frame, the A. O, Smith plant could have gone full blast forever, and many, many labour hours could have been saved. At least until the mid-Fifties, when this hypothetical all-Model-T industry was swamped with superior European imports.

That is not, of course, what happened, and it is the flip side of mass production. When all aspects

of industrial manufacture are taken into account, we find that mass production is

a substitute for more

labour-intensive manufacture, of a certain kind. The design input has been reduced –and, in the case of the automated

frame factory, manufacturing skill. The

question is –who pays the price?

In an early post, I talked about how the United States

fought World War II with crap weapons, and how it all worked out just fine.

The surface naval battles off Guadalcanal in 1942—3 were my example, and a good one. Virtually every concrete American naval weapon system

with a Japanese counterpart,was

substantially inferior to that counterpart. It turns out that the Navy Department had been saving money by sacrificing design. It's the American way (of production)! As it happens, I should probably have talked about the Sherman tank, still a touchy subject for the United States Army. Tanks are automotive, like tractors and cars, and the United

States really did sacrifice at the design level in order to have more tanks.

Since this is an industrial strategy, the analogy extends. If the Sherman tank was obsolescent in 1944 and obsolete by 1945, so too was the Fordson tractor simply not a good business by 1928. In promoting the Fordson in 1916, the County War Board argued that "Farmers spent $.95 per acre plowing with a Fordson compared to feeding eight horses for a year and paying two drivers, which cost $1.46 per acre." This is a bit disingenuous, in that the Fordson also required a driver and a co-driver, the latter taking care of the accessory hitched to the back, which was especially important given that the Fordson tended to rear back and flip over if the accessory stopped moving, as when the plough hit a rock. Redesigning the Fordson's final drive and giving it a universal, powered hitch, would have helped.

More importantly, in any regime in which the farmer didn't buy animal fodder, the math stops making sense. When Ford discontinued the Fordson, in 1928, American farms were beginning to revert to autarkist strategies in the face of price supports and other supply management techniques. Had the Fordson been the only tractor in the market, the Great Depression would have led to the de-automation of the American farm. It was not, of course, but many farmers really did give up on tractors in the Great Depression.

The Andersons managed a 600 acre farm by growing only wheat. This doesn't deplete their soil in part because they use a fallow rotation, in part because they buy nitrates and potash to fertilise their fields, and early herbicides to keep down weeds. I haven't been able to find the post where I reported on American sugar beet farmes, and their concern that sugar imports would damage a crop that was good for the soil and which produced a great deal of fodder as well, but I could point instead to Professor Collingham's particular interest, the rapidly expanding American soybean crop of the war years. The classic Norfolk four-course rotation minimises farm market inputs by replenishing soil nitrogen with legumes as well as by holding down weeds with regular inter-row ploughing between the turnips (sugar beets.) Soybeans, which are sold, pressed for their oil, and then processed back into cake for fodder, are much more intimately involved in the larger market economy than the clover and vetch of the old Norfolk rotation, but it is still basically the same thing. The Andersons are farming in the American way. Less labour means less production --but this is obscured by their ability to substitute market inputs like fertilisers and tractors for the less saleable products of a full rotation.

Of course, had market agriculture gone into retreat after the war, and had they retreated into autarkism, the wheat crop would have fallen, the labour input per acre would have risen, and they would probably have leased some of their land, becoming squires in the process.** Of course, that's crazy talk. Who ever heard of de-automation?

(Except for the people laid off in 1958 when Automotive Products closed its automatic frame factory, that is.)

Since this is an industrial strategy, the analogy extends. If the Sherman tank was obsolescent in 1944 and obsolete by 1945, so too was the Fordson tractor simply not a good business by 1928. In promoting the Fordson in 1916, the County War Board argued that "Farmers spent $.95 per acre plowing with a Fordson compared to feeding eight horses for a year and paying two drivers, which cost $1.46 per acre." This is a bit disingenuous, in that the Fordson also required a driver and a co-driver, the latter taking care of the accessory hitched to the back, which was especially important given that the Fordson tended to rear back and flip over if the accessory stopped moving, as when the plough hit a rock. Redesigning the Fordson's final drive and giving it a universal, powered hitch, would have helped.

More importantly, in any regime in which the farmer didn't buy animal fodder, the math stops making sense. When Ford discontinued the Fordson, in 1928, American farms were beginning to revert to autarkist strategies in the face of price supports and other supply management techniques. Had the Fordson been the only tractor in the market, the Great Depression would have led to the de-automation of the American farm. It was not, of course, but many farmers really did give up on tractors in the Great Depression.

The Andersons managed a 600 acre farm by growing only wheat. This doesn't deplete their soil in part because they use a fallow rotation, in part because they buy nitrates and potash to fertilise their fields, and early herbicides to keep down weeds. I haven't been able to find the post where I reported on American sugar beet farmes, and their concern that sugar imports would damage a crop that was good for the soil and which produced a great deal of fodder as well, but I could point instead to Professor Collingham's particular interest, the rapidly expanding American soybean crop of the war years. The classic Norfolk four-course rotation minimises farm market inputs by replenishing soil nitrogen with legumes as well as by holding down weeds with regular inter-row ploughing between the turnips (sugar beets.) Soybeans, which are sold, pressed for their oil, and then processed back into cake for fodder, are much more intimately involved in the larger market economy than the clover and vetch of the old Norfolk rotation, but it is still basically the same thing. The Andersons are farming in the American way. Less labour means less production --but this is obscured by their ability to substitute market inputs like fertilisers and tractors for the less saleable products of a full rotation.

Of course, had market agriculture gone into retreat after the war, and had they retreated into autarkism, the wheat crop would have fallen, the labour input per acre would have risen, and they would probably have leased some of their land, becoming squires in the process.** Of course, that's crazy talk. Who ever heard of de-automation?

(Except for the people laid off in 1958 when Automotive Products closed its automatic frame factory, that is.)

*For example, did you know that American manufacturing disemployment is due to automation, not free trade and a high dollar? It's confusing because all the automation happened after China received Most Favoured Nation status, and wasn't accompanied by any changes in productivity. It's almost like all the robot-factories are in another country. And, also, maybe didn't actually have robots, although that's just speculation.

**(Hmm. The farm plots are still big, but the patchwork looks suspiciously four-coursey. Ford Township, of 96 square miles, has a population of 456. Dodge City, the county seat, has a population of 27,340. Per the Census, the racial makeup of the city was 72.5% White, 2.5% African American, 1.1% American Indian, 1.6% Asian, 0.2% Pacific Islander, 19.3% from other races, and 2.9% from two or more races. Hispanics and Latinos of any race were 57.5% of the population.

I take it you don't mean whites and Latinos together accounted for 130% of the population?

ReplyDeleteThe way the American census does it, the "Hispanics and Latinos of any race" includes people who check the "White" and the "Hispanic and Latino" box, and the "White" category includes everyone who checks that box. They're double-counted, in other words. Call it the "Emilio Estevez" effect.

ReplyDeleteI'm guessing that there's a meat packing plant in Dodge City. The industry employs a large proportion of Latin American immigrants, particularly Central Americans. There are other reasons why Dodge City might have so many Latinos, however, and I can't even begin to guess what country-versus-city politics might look like in Ford County these days.